Register now for the upcoming webinar "Advancing Rotating Detonation Engines Using CFD" – May 8, 10:30 AM – 11:30 AM CDT

The new version of CONVERGE offers improved simulation speed and accuracy, a host of new models, and enhanced post-processing capabilities. Learn more!

Join us at Politecnico di Torino on June 11 for a free workshop focused on innovative, state-of-the-art solutions to reduce carbon emissions from transportation. Learn more!

Learn how to use CONVERGE and boost your engineering career through this free professional development program.

Hear about the latest advancements in sustainable hydrogen technologies from leading members of industry and academia on May 15 at the University of Orléans. Learn more!

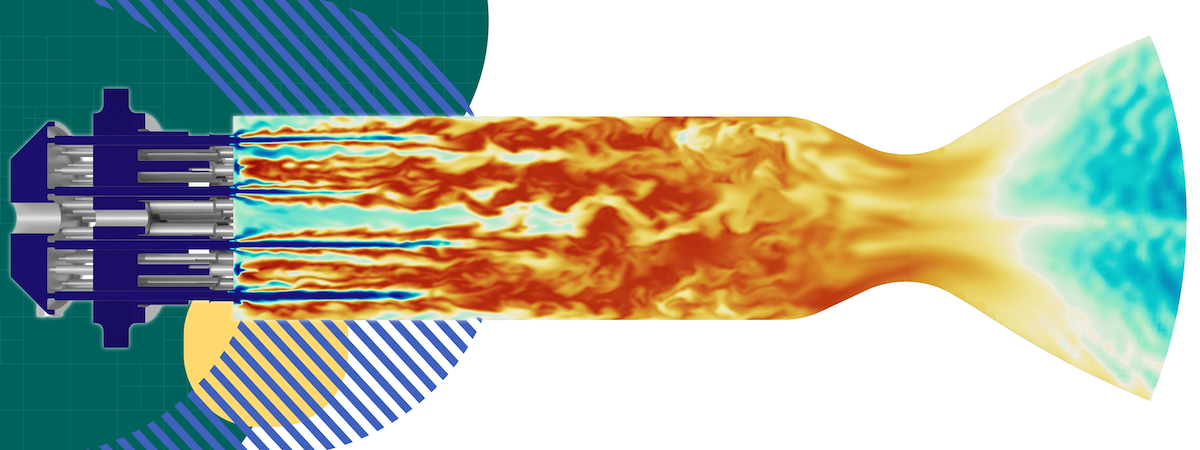

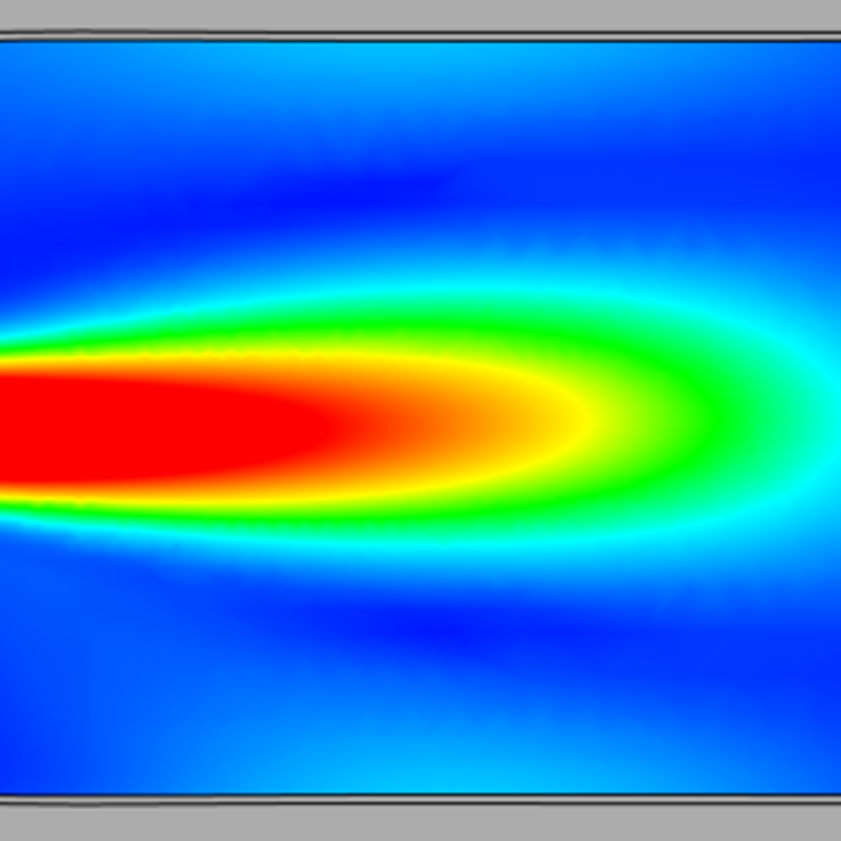

Innovation in engineering benefits from accurate, efficient, and reliable tools. As a leading computational fluid dynamics (CFD) software for simulating three-dimensional fluid flow, CONVERGE is designed to facilitate your innovation process. CONVERGE features truly autonomous meshing, state-of-the-art physical models, a robust chemistry solver, and the ability to easily accommodate complex moving geometries, so you can take on the hard CFD problems.

We specialize in fast, predictive CFD, so you get accurate simulation results quickly. CONVERGE gives you an edge in a competitive market—you can rapidly explore various design options, predict problem areas in your product before manufacturing, and optimize your product design using CONVERGE’s advanced model optimization tools. And since CONVERGE leads the way in CFD automation, you can spend your time engineering instead of meshing.

Please fill out the information below to access this resource.